TM-9-2350-311-34-2 - Page 258 of 552

TM 9-2350-311-34-2

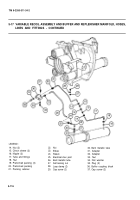

5-16 VARIABLE RECOIL ASSEMBLY, HOSES, LINES, AND FITTINGS

This task covers:

a. Removal

b. Installation

INITIAL SETUP

Tools

Artillery and turret mechanic’s tool kit

(SC 5180-95-CL-A12)

Materials/Parts

Cap and plug set (item 10, Appx B)

Cotter pins (2) (item 46, Appx E)

Locknuts (3) (item 2, Appx E)

LockWashers (4) (item 84, Appx E)

Packing retainer (item 61, Appx E)

Plastic bag (item 6, Appx B)

Preformed packing (item 63, Appx E)

Preformed packing (item 99, Appx E)

Preformed packings (3) (item 67, Appx E)

Preformed packings (4) (item 155, Appx E)

References

TM 9-2350-311-20-2

Equipment Condition

Replenisher assembly pressure discharged (para 5-14)

Discharge hydraulic pressure (TM 9-2350-311-20-2)

a. Removal

Eye protection will be worn when performing maintenance procedures on all hydraulic components

to avoid injury to personnel.

All hydraulic lines and ports must be capped to prevent contaminants from entering the hydrau-

lic system and causing internal damage to hydraulic components.

All serviceable components must be placed in plastic bags to prevent contamination of hydrau-

lic system during installation.

NOTE

All hydraulic lines and components must be tagged before removal for identification during in-

stallation.

The removal of hydraulic tubes and fittings must be restricted to those items that are to be re-

placed. Therefore, the legends in this chapter are for identification only.

For removal, follow illustration and legend as a guide. Discard all locknuts, preformed packings, and packing

retainers.

b. Installation

When installing any hydraulic fitting, tighten fitting to aline with the connecting lines. Repositioning

can loosen threads, cause leaks, and damage preformed packings.

5-112

Back to Top