TM-9-2350-311-34-2 - Page 270 of 552

TM 9-2350-311-34-2

6-1

POWER PACK ASSEMBLY-CONTINUED

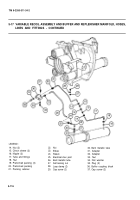

c. Inspection and Repair

1

inspect fluid level gage (27). Replace if bent or distorted.

2

Inspect fluid filter element (22). Replace if cut or torn.

3

Inspect tube assembly (23). Replace if damaged.

4

Inspect power pack reservoir (24). Replace if cracked or if end surfaces are rough or distorted.

5

Inspect upper shaft coupling half (42), flexible insert (17), and lower shaft coupling half (19). Replace parts

that are cracked, distorted, or worn.

6

Inspect mount assembly (33). Replace if cracked, distorted, or damaged.

7

Inspect rotary pump (39). Replace if defective.

8

Inspect two plain studs (47). Replace if bent, distorted, cracked, or damaged.

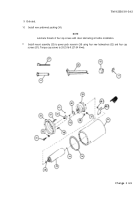

d. Assembly

All parts and inside surfaces must be free of contaminants during assembly.

1

If removed, install new spring pin (48) and two plain studs (47). Torque plain studs to 21-25 lb-ft (28-34

N•m).

1.1

If removed, secure identification plate (48.2) onto power pack reservoir (24) using four drive screws (48.1).

2

Install new preformed packing (46) on filter assembly/body assembly (45).

3

Install rotary pump (39) on filter assembly/body assembly (45).

4

Install new preformed packing (44) on filter assembly/body assembly (45).

5

Install setscrew (41) in upper shaft coupling half (42). Install machine key (43) and upper shaft coupling half

on rotary pump (39) shaft.

6

Install new preformed packing (40) on rotary pump (39).

7

Before installing, flush new filter assembly (45) with hydraulic fluid.

8

Install rotary pump (39) onto mount assembly (33) with two new lo&washers (38) and two hex nuts (37).

Torque hex nuts to 20-25 lb-ft (27-34 N•m).

6-8 Change 2

Back to Top