TM-9-2815-205-24 - Page 487 of 856

ADJUSTMENT

NOTE

A 0.025 inch (0.635 mm) thickness gage (cold engine) must pass freely between end of

one valve stem (Figure 1, Item 5) and rocker arm bridge (Figure 1, Item 4).

A 0.027 inch (0.686 mm) thickness gage (cold engine) must not pass through bridge

clearance. Mark each rocker arm with a crayon or marker after adjustment.

7.

Check valve bridge clearance with thickness gage. If clearance is not within limits, repeat procedures in

Steps 3–6.

8.

Adjust all exhaust valves following Steps 1–7.

FUEL INJECTOR TIMING

CAUTION

Do not rotate crankshaft in counterclockwise direction using crankshaft bolt. Crankshaft

bolt can loosen and serious engine damage may result if crankshaft bolt is not securely

tightened to crankshaft.

NOTE

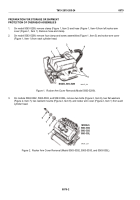

Time all fuel injectors during one full revolution of crankshaft. Firing order: 1L, 3R, 3L, 2R,

2L, and 1R (Figure 2).

1

2

3

1

FRONT

LEFT

VIEW

RIGHT

VIEW

FIRING ORDER

1L, 3R, 3L, 2R, 2L, 1R

2

3

MAINT_216

Figure 2.

Firing Order (1L, 3R, 3L, 2R, 2L, 1R).

1.

Using crankshaft end bolt, rotate crankshaft clockwise until exhaust valve stems (Figure 3, Item 5) are fully

depressed on cylinder to be timed.

2.

Hold fuel injector push rod (Figure 3, Item 8) and loosen push rod locknut (Figure 3, Item 7).

TM 9-2815-205-24

0078

0078-3

Back to Top