TM-9-2815-205-24 - Page 546 of 856

REPAIR OR REPLACEMENT - Continued

(3)

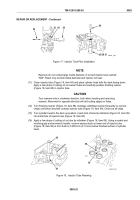

Grind top surface of valve seat with 15 degree grinding wheel to narrow seat width to dimensions

shown. Adjust the 31 degree face (Figure 13, Item 76) relative to center of valve face

(Figure 13, Item 75) using 15 and 60 degree grinding wheels.

NOTE

Grinding will reduce thickness of valve seat and cause valve to recede into

cylinder head. Replace valve seat if valve recedes beyond limits.

(4)

After grinding is completed, clean valve seat thoroughly. Measure concentricity of valve seat in

relation to valve guide. If runout exceeds 0.002 inch (0.05 mm), check for bent or worn valve

guide before regrinding valve seat.

0.047–0.078 in.

(1.19–1.98 mm)

0.220–0.224 in.

(5.59–5.69 mm)

0.031 in. (0.79 mm)

MINIMUM

75

76

MAINT_259

Figure 13.

Cylinder Head Valve Seat Centricity Measurement.

TM 9-2815-205-24

0083

0083-16

Back to Top