TM-9-2815-205-24 - Page 542 of 856

REPAIR OR REPLACEMENT - Continued

3.

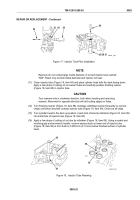

Exhaust valve guides inspection and replacement procedures:

a.

Inspect valve guides (Figure 10, Item 72) for fractures, chipping, scoring, or excessive wear. Measure

inside diameter of valve guide and diameter of valve stem to determine clearance between guide and

valve stem. If clearance exceeds 0.005 inch (0.125 mm), replace valve guide.

b.

Replace valve guide as follows:

c.

Support cylinder head, bottom side up, on three inch thick wood blocks.

d.

Using valve guide remover (Figure 10, Item 68), drive valve guide (Figure 10, Item 72) out of

cylinder head.

e.

Place cylinder head right side up in press.

f.

Place valve guide (Figure 10, Item 72) squarely in bore. Using valve guide installer

(Figure 10, Item 69), press guide until tool contacts cylinder head.

4.

Valve seats inspection and replacement procedures:

a.

Inspect valve seats (Figure 10, Item 70) for excessive wear, pitting, cracking, or improper seat angle.

b.

Replace as follows:

(1)

Place cylinder head on wood blocks with fire deck side up.

(2)

Using valve seat installing tool (Figure 10, Item 71), remove valve seat (Figure 10, Item 70).

(3)

Clean valve seat counter bore in cylinder head and inspect for concentricity, flatness,

and cracks.

NOTE

Valve seat counterbore has a diameter of 1.159–1.160 inches (29.44–29.46 mm)

and a depth of 0.294–0.306 inch (7.47–7.77 mm). Counterbores must be

concentric with valve guides within 0.003 inch (0.08 mm) total indicator reading.

(4)

Immerse cylinder head in water heated to 180–200°F (82–93°C) for 30 minutes or cool insert

with liquid nitrogen.

TM 9-2815-205-24

0083

0083-12

Back to Top