TM-9-2815-205-24 - Page 703 of 856

INSPECTION-ACCEPTANCE AND REJECTION CRITERIA

NOTE

Overheating or burned spots on piston skirt or dome may indicate an obstruction in

connecting rod oil passage.

1.

Examine piston skirt and dome for score marks, cracks, damaged ring groove lands, or indications of

overheating. Using a crocus cloth, remove light score marks. Replace piston skirt or dome severely scored

or overheated.

2.

Check cylinder liner and block bore for excessive out of round, taper, or high spots which could cause failure

of piston (WP 0097).

CAUTION

Do not polish or refinish piston pin. Hand polishing or refinishing will destroy precision

finish and result in rapid bushing wear.

3.

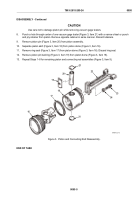

Inspect piston pin (Figure 4, Item 20) for signs of fretting.

4.

New piston pin has diameter of 1.3746–1.3750 inches (34.915–34.925 mm). Replace piston pin if worn to

diameter of 1.3730 inches (34.874 mm) or less.

1.3746–1.3750 in.

(34.915–34.925 mm)

20

MAINT_374

Figure 4.

Piston Pin Inspection.

5.

Check connecting rod for visual damage. Discard rod if bent, had previous bearing failure, was overheated

(blued) at top or bottom end, is fretted at split line between rod and cap, or has excessive pound in of bolt

head or nut.

6.

Check for cracks by magnetic particle inspection method (reference ASTM E1444).

7.

Inspect connecting rod bearing bores for burrs or foreign particles. Clean up minor burrs with crocus cloth

using circular motion.

TM 9-2815-205-24

0095

0095-7

Back to Top