TM-9-2815-205-24 - Page 704 of 856

INSPECTION-ACCEPTANCE AND REJECTION CRITERIA - Continued

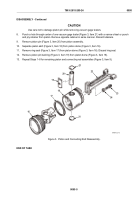

8.

If new connecting rod is required, stamp cylinder number on connecting rod (Figure 5, Item 22) and cap

(Figure 5, Item 7) using metal stamping die set.

CRITICAL AREA

ACCEPTABLE LIMITS

NONCRITICAL

AREA

A

A

22

7

SECTION

A-A

VIEW A

VIEW A

DO NOT USE OR ATTEMPT TO

REPAIR RODS WITH INDICATIONS

OVER 0.005 in . (0.13 mm) DEEP

EXTENDING OVER EDGES OF "H"

SECTION ON BOTH SIDES OF

FLANGE. SHADED AREAS ARE

MOST HIGHLY STRESSED.

START OF FATIGUE CRACK

RESULTING FROM OVERLOADING

(DUE TO HYDROSTATIC LOCK).

DO NOT ATTEMPT TO REPAIR.

EXAMPLE OF A TRANSVERSE

INDICATION THAT DOES NOT

FOLLOW LONGITUDINAL FORGING

FLOW LINES CAN BE EITHER A

FORGING LAP, HEAT TREAT CRACK,

OR START OF A FATIGUE CRACK.

INDICATIONS IN NONCRITICAL

AREAS ARE ACCEPTABLE UNLESS

THEY ARE OBVIOUS CRACKS

WITHOUT MAGNETIC INSPECTION.

LONGITUDINAL INDICATIONS

FOLLOWING FORGED FLOW LINES

ARE USUALLY SEAMS AND ARE NOT

HARMFUL IF LESS THAN 0.03 in.

(0.8 mm) DEEP.

DETERMINE DEPTH

BY GRINDING A SMALL AREA NEAR

THE CENTER OF THE INDICATION.

ACCEPT TRANSVERSE INDICATIONS (ACROSS

FLOW LINES) HAVING A MAXIMUM GRINDING

LENGTH OF 0.5 in. (12.7 mm) AND DEPTH OF

0.016 in. (0.41 mm) AFTER COMPLETE REMOVAL.

AN EXCEPTION IS A ROD HAVING AN INDICATION,

WHICH EXTENDS OVER THE EDGE OF THE "H"

SECTION AND IS PRESENT ON BOTH SIDES OF

THE FLANGE. THEN THE MAXIMUM ALLOWABLE

DEPTH IS 0.005 in. (0.13 mm). SEE SECTION A-A.

GRINDING NOTES:

TAKE CARE IN GRINDING

OUT

INDICATIONS TO ENSURE PROPER

BLENDING OF GROUND AREA

INTO UNGROUND SURFACE SO AS

TO FORM A SMOOTH CONTOUR.

POOR

PRACTICE

GOOD

PRACTICE

EXAMPLE OF AN

INDICATION FOLLOWING

LONGITUDINAL FORGING

FLOW LINES.

MAINT_375

Figure 5.

Connecting Rod Inspection Procedures.

9.

Inspect bearing shells for scoring, pitting, flaking, etching, and dirt grooving. If defective, discard

bearing shells.

10.

Discard bearing shells with bright spots on backs indicating movement in bearing caps or supports.

TM 9-2815-205-24

0095

0095-8

Back to Top