TM-9-2815-205-24 - Page 710 of 856

ASSEMBLY - Continued

2.

Installation - Piston Rings Procedures:

a.

Lubricate piston rings and piston with engine oil before installing rings.

CAUTION

Do not allow ends of oil ring expanders to overlap. An overlapped expander

will cause oil ring to protrude beyond allowable limits and result in breakage

when piston is inserted in piston ring compressor during installation in

cylinder liner.

Do not cut or grind ends of expanders to prevent overlapping. Cutting or

grinding ends will decrease expanding force on oil control rings and result in

high lubricating oil consumption.

b.

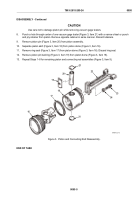

Install two oil ring expanders (Figure 11, Item 15) in oil control ring grooves in piston skirt

(Figure 11, Item 18) with legs of free ends pointing toward bottom of piston.

WARNING

Rings are extremely sharp. Do not grasp or graze sharp edges of oil control rings with

bare hands. Failure to comply may result in injury to personnel.

CAUTION

Do not spread rings anymore than necessary to slip them over piston. Ring breakage

and overstressing will result.

NOTE

Install oil control rings in lower groove by hand.

Upper oil control ring groove requires one thick ring and lower groove requires

two thin rings.

Install upper oil control ring in lower groove with scraper edge facing up. Install

lower oil control ring with scraper edge facing down.

c.

Install lower thin oil control ring (Figure 11, Item 14), scraper edge down, in groove C

(Figure 11, Item C) (lower groove) with gap in ring 180 degrees from gap in expander

(Figure 11, Item 15). Then install upper ring (Figure 11, Item 14), scraper edge up, in groove C

(Figure 11, Item C) with gap 180 degrees from gap in lower ring.

TM 9-2815-205-24

0095

0095-14

Back to Top