TM-9-2815-205-34 - Page 379 of 596

(g)

(h)

(i)

(j)

(k)

TM 9-2815-205-34

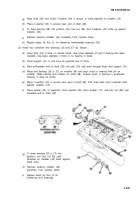

Align shaft (28) and install C-washer (39) in groove in shaft adjacent to installer (33).

Place C-washer (40) in groove near end of shaft (28).

To draw bearing (29) into position, turn hex nut (38) until C-washer (40) butts up against

installer (34).

Remove bearing installer (34) assembly from cylinder block.

Repeat steps (a) thru (j) for remaining intermediate bearings (29).

(2) Install four camshaft end bearings (25 and 27) as follows:

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

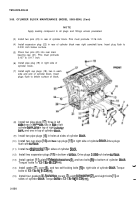

Insert pilot (24) in bore of cylinder block. Use small diameter of pilot if bearing has been

installed. Use large diameter if there is no bearing in block.

Insert support (41) in end bore at opposite end of block.

Start unthreaded end of shaft (28) into pilot (24) and push through block and support (41).

Place end bearing (25 or 27) on installer (34) and align notch in bearing with pin on

installer. Slide bearing and installer on shaft (28). Ensure notch in bearing is positioned

properly in bore as shown.

Place C-washer (40) in groove near end of shaft (28). Pull shaft back until C-washer butts

against installer (34).

Place spacer (35) (if required), thrust washer (36), plain washer (37), and hex nut (38) over

threaded end of shaft (28).

To draw bearing (25 or 27) into

position, turn hex nut 38) until

shoulder on installer (34) butts against

block bore.

Remove bearing installer (34)

assembly from cylinder block.

Repeat steps (a) thru (h) for

remaining end bearings.

3-249

Back to Top