TM-9-2815-205-34 - Page 378 of 596

TM 9-2815-205-34

3-55. CYLINDER BLOCK

d. Assembly

MAINTENANCE (MODEL 5063-5398) (Cont)

NOT E

•

•

•

•

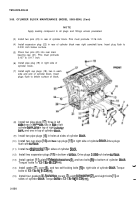

Camshaft intermediate bearings must be installed prior to installing camshaft end

bearings and are pressed into cylinder block from outboard end of bore.

Notch in front end bearing and front intermediate bearing is toward front of engine.

Notch in rear end bearing and rear intermediate bearing is toward rear of engine.

Camshaft replacement bearings are available with either standard or oversized

outside diameter and standard or undersized inside diameters as shown in Table

3-13.

Camshaft bearing remover and installer set is designed for use with standard size

bearings. Set can be used to remove and install undersize bearings if outside diameter

of pilot, installers, and remover is reduced by 0.020 inch.

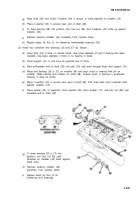

(1) Install four intermediate camshaft

bearings (29) as follows:

(a)

(b)

(c)

(d)

Insert large diameter of pilot (24) in

camshaft end bearing bore in block.

Insert intermediate bearing (29) into

outboard end of camshaft bore.

Ensure notch is positioned properly in

bore as shown.

Start unthreaded end of shaft (28) in

pilot (24) and push shaft through

entire length of cylinder block bores.

Slide installer (33) on shaft (28) until

TABLE 3-13. CAMSHAFT BEARING COLOR CODE

Bearing

Color Code

Outside

Position

Current

Former

Diameter

Brown

Black

Standard

End

Brown

Yellow

Oversize

lnter-

Orange

Red

Standard

mediate

Orange

Blue

0.010

Oversize

locating pin engages notch in bearing

(29).

NOT E

(e) Slide installer (34) on end of shaft (28)

with large diameter inserted into end

of block bore.

(f) Place spacer (35), thrust washer (36),

plain washer (37), and hex nut (38)

over threaded end of shaft (28).

Inside

Diameter

Standard, 0.010, &

0.020 Undersize

Standard

Standard, 0.010, &

0.020 Undersize

Standard

Use J-7593-15 installer when

installing right front or left rear

intermediate

bearing. Use

J-7593-3 installer when install-

ing left front or right rear

intermediate bearing.

3-248

0.010

Back to Top