TM-9-2815-205-34 - Page 368 of 596

TM 9-2815-205-34

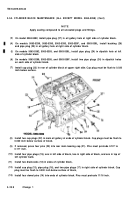

3-54. CYLINDER BLOCK MAINTENANCE (ALL EXCEPT MODEL 5063-5398) (Cont)

NOT E

Apply sealing compound to all uncoated plugs and fittings.

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

On model 5063-5392, install pipe plug (27) in oil gallery hole at right side of cylinder block.

On models 5063-5299, 5063-5395, 5063-5393, 5063-539F, and 5063-539L, install bushing (26)

and pipe plug (25) in oil gallery hole at right side of cylinder block.

On models 5063-5392, 5063-5393, and 5063-539L, install pipe plug (24) in dipstick hole at left

side of cylinder block.

On models 5063-5299, 5063-5395, and 5063-539F, install two pipe plugs (24) in dipstick holes

on each side of cylinder block.

Install cup plug (23) in rear of cylinder block at upper right side. Cup plug must be flush to 0.030

inch below surface.

Install two cup plugs (22) in main oil gallery at ends of cylinder block. Cup plugs must be flush to

0.030 inch below surface of block.

If removed, press four pins (20) into rear main bearing cap (21). Pins must protrude 0.107 to

0.117 inch.

Install four pipe plugs (19); one in left side of block, two in right side of block, and one in top of

left cylinder bank.

Install two draincocks (18) in sides of cylinder block,

Install cup plug (15), pipe plug (16), and two pipe plugs (17) in right side of cylinder block. Cup

plug must be flush to 0.030 inch below surface of block,

Install four dowel pins (14) into ends of cylinder block. Pins must protrude 11/16 inch.

3-238

Change 1

Back to Top