TM-9-2815-205-34 - Page 363 of 596

TM 9-2815-205-34

b. Cleaning

NOT E

Remove all plugs from cylinder block except flush mounted dowel pins.

(1) Scrape all gasket material from cylinder block.

(2)

(3)

(4)

WARNING

•

Dry cleaning solvent P-D-680 is toxic and flammable. Wear protective goggles

and gloves and use in a well-ventilated area. Avoid contact with skin, eyes, and

clothes. Do not breathe vapors. Do not use near open frame or excessive heat.

The flash point is 100-138°F (38-50°C). If you become dizzy while using cleaning

solvent, get fresh air immediately and seek medical aid. If contact with eyes is

made, wash with water and get medical aid immediately.

•

Compressed air used for cleaning purposes will not exceed 30 PSI. Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.)

Clean inner and outer surfaces of cylinder block with cleaning solvent.

Clean water, air, and oil passages with bore brush. Flush passages with cleaning solvent and

blow out with compressed air.

Dry cylinder block with compressed air.

c. Inspection

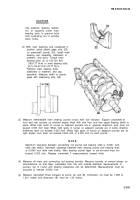

(1) Inspect seal ring grooves in cylinder

bores for evidence of pitting and erosion.

•

•

•

(2)

(3)

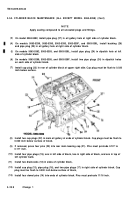

NOT E

Use standard size cylinder liner

if diameter (A) is less than

4.5235 inches, diameter (B) is

less than 4.4900 inches, and

diameters (C) and (D) are less

than 4.3595 inches.

See Table 3-10 for cylinder bore diameters requiring oversize cylinder liners.

When oversize liner is used, stamp amount of oversize on top of cylinder bore adjacent

to liner counterbore using metal stamping die set.

Measure entire bore of each cylinder with cylinder bore gage. Take measurements at positions

(A), (B), (C), and (D) in bore on axis 90 degrees apart as shown.

Check cylinder bore taper and out of round. Neither may exceed 0.0015 inch.

3-233

Back to Top