TM-9-2815-205-34 - Page 356 of 596

TM 9-2815-205-34

3-53. CRANKSHAFT MAINTENANCE (Cont)

f. Assembly

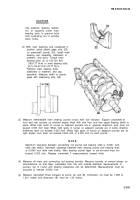

(1) Using crankshaft plug installer, install

three pipe plugs (19) into crankshaft (13).

Torque plugs to 10-12 Ib-ft (14-16 N

.

m).

(2) If removed, install oil pump drive gear

(20) as follows:

(a)

(b)

(c)

(d)

Lubricate inside diameter of oil pump

drive gear with engine oil.

Start gear on crankshaft with

chamfered edge of gear toward

crankshaft journals.

NOT E

The end of bore in installer (26) must contact the end of crankshaft to correctly position

the drive gear.

Place oil pump drive gear installer (26) over crankshaft and against drive gear (20). Force

gear on crankshaft until bore in installation tool contacts end of crankshaft.

Using slip torque adapter, check press fit of drive gear to crankshaft. Drive gear should not

slip on crankshaft with a torque of 100 Ib-ft (136 N

.

m).

NOT E

Do not exceed torque of 100 Ib-ft (136 N-m) on slip torque adapter. If gear slips on

crankshaft, install new drive gear.

(3) Install Woodruff key (18) in keyway of crankshaft. Start crankshaft gear (17) on crankshaft with

timing marks on rim of gear facing out and keyway in gear in alignment with Woodruff key.

(4) Place crankshaft gear installer (27) against rear face of

shoulder on crankshaft.

g. Installation

CAUTION

When a new or reground crankshaft is installed, all

bearing shells and thrust washers must be installed.

gear (17). Drive gear tight against

new main and connecting rod

(1)

(2)

3-226

Install upper main bearing shells (14) in block. If bearings are being reused, install them in

same iocations from which they were removed.

Apply clean engine oil to upper bearing shells and completely around crankshaft main bearing

journals.

Back to Top