TM-9-2815-205-34 - Page 354 of 596

TM 9-2815-205-34

3-53. CRANKSHAFT MAINTENANCE (Cont)

CAUTION

Install upper and lower bearing

shells as a set. Do not replace

one main bearing shell alone.

Always install all new bearing

shells with new crankshaft.

NOT E

Lower bearing shells, which

carry the load, will normally

show signs of distress before

upper bearing shells.

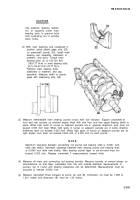

(9) Discard main bearings with signs of

scoring, pitting, flaking, etching,

overheating, or loss of overlay.

e. Measurements

(1)

(2)

Using micrometer and ball attachment

(22), measure thickness of bearing shells

(11 and 14) at point (C), 90 degrees from

parting line. Replace if minimum

thickness is less than 0.1230 inch. A

standard bearing is 0.1240 to 0.1245 inch

thick. Refer to Table 3-9 for thickness of

bearings.

NOT E

If clearance between any

crankshaft journal and its

bearing shells exceeds 0.0060

inch, replace all bearing shells.

Clearance for new parts is

0.0010 to 0.0040 inch.

Check main bearings to crankshaft

journals clearance using step (a) or (b):

(a) With crankshaft removed, measure

outside diameter of crankshaft main

bearing journals and inside diameter

of main bearing shells in place with

required torque. When installed,

bearing shells are 0.001 inch larger in

diameter at parting line than 90

degrees from parting line.

TABLE 3-9. CRANKSHAFT BEARING

SHELL THICKNESS

BEARING

NEW BEARING

MINIMUM USED

SIZE

THICKNESS *

THICKNESS *

Standard

0.1240-0.1245 in.

0.1230 in.

(3.167-3.180 mm)

(3.124 mm)

0.002 in.

0.1250-0.1255 in.

0.1240 in.

Undersized

(3.175-3.188 mm)

(3.150 mm)

0.010 in.

0.1290-0.1295 in.

0.1280 in.

Undersized

(3.277-3.289 mm)

(3.251 mm)

0.020 in.

0.1340-0.1345 in.

0.1330 in.

Undersized

(3.404-3.416 mm)

(3.378 mm)

0.030 in.

0.1390-0.1395 in.

0.1380 in.

Undersized

(3.531-3.543 mm)

(3.505 mm)

*Thickness 90 degrees from parting line of bearing.

3-224

Back to Top