TM-9-2815-205-34 - Page 350 of 596

TM 9-2815-205-34

3-53. CRANKSHAFT MAINTENANCE

This task covers: a. Removal

b. Disassembly

c. Cleaning

d. Inspection

e. Measurements

f. Repair

g. Assembly

h. Installation

INITIAL SETUP

MODELS

All

TOOLS AND SPECIAL TOOLS

Tool kit, general mechanics (App B, Item 107 )

Wrench, torque (App B, Item 116)

Indicator, dial, magnetic base (App B, Item 54 )

Micrometer set(App B, Item 73 )

Micrometer 0-1 inch

Micrometer 2-3 inch

Micrometer 3-4 inch

Three-leg puller (App B, Item 81 )

Gage, bore (App B, Item 35 )

Sling (App B, Item 93 )

Die set, metal stamping, hand (App B, Item 20 )

Ball attachment, micrometer (App B, Item 8 )

Gage set, telescoping (App B, Item 33 )

Installer, crankshaft gear (App B, Item 57 )

Installer crankshaft plug (App B, Item 60 )

Installer, oil pump ear (App B, Item 65 )

Installer, crankshaft pulley (App B, Item 61 )

Adapter, slip torque (App B, Item 4 )

Puller, mechanical (App B, Item 80 )

MATERIALS/PARTS

8

Screws, self-locking (App F, Item 152)

EXPENDABLE/DURABLE SUPPLIES

Oil, engine (App C, Item 26)

Plastic gage (App C, Item 16)

Crocus cloth (App C, Item 10)

Emery cloth (App C, Item 13)

Oil, fuel (App C, Item 27)

International Compound No, 2 (App C, Item 21)

Cleaning solvent (App C, Item 9)

Stone, sharpening X-fine (App C,

Item 51)

Washers, flat (App C, Item ’55)

3

Nuts (App C, Item 24)

EQUIPMENT CONDITION

Para Description

3-50 Cylinder kits removed (models 5063-5299,

5063-5395, and 5063-5395)

3-51 Cylinder kits removed (models 5063-5392,

5063-5393, 5063-539F, and 5063-539L)

a. Removal

(1)

(2)

(3)

For all except model 5063-5398, remove eight small self-locking screws (1), eight hardened

washers (2), eight large bolts (3), eight hardened washers (4), and four stabilizer plates (5) from

bottom of cylinder block. Discard self-locking screws.

For model 5063-5398, remove sixteen bolts (6), sixteen washers (7), four supports (8), and

eight spacers (9) from bottom of cylinder block.

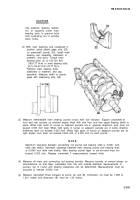

CAUTION

Keep main bearing caps and main bearing shells in their original position. Main bearing

caps are numbered 1, 2, 3, and 4. Upper bearing shell has an oil hole and groove for

lubrication, and lower bearing shell is smooth with no groove or oil hole.

Remove four main bearing caps (10) from cylinder block. Remove four lower bearing shells (11)

and two lower thrust washers (12) (rear cap only) from caps and mark with corresponding

bearing number.

(3-219 blank)/3-220

Change 1

Back to Top