TM-9-2815-205-34 - Page 357 of 596

TM 9-2815-205-34

WARNING

(3)

(4)

If hoist and sling are not available, use two or more men to remove crankshaft.

Crankshaft is heavy and awkward to handle. Serious injury can result if

crankshaft is dropped.

CAUTION

D

O

not damage journals or main bearing shells when lowering crankshaft into position.

Damage will result in short component life.

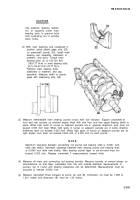

Place crankshaft (13) in upper bearing

shells in cylinder block.

Install upper crankshaft thrust washers

(5)

(6)

(7)

(15) on each side of rear main bearing

support with grooved side of thrust

washers toward crankshaft thrust

surfaces.

NOT E

•

Install bearings in same bear-

ing caps from which removed.

Ž

All crankshaft bearing shells

have a tang for proper align-

ment. Upper bearing shells

have oil holes for lubrication.

Install lower main bearing shells (11) in

bearing caps (10). Install two lower thrust

washers (12) on rear main bearing cap

with thrust washers over dowel pins in

sides of main bearing cap and grooved

side of washer facing crankshaft thrust

surface.

NOT E

Main bearing caps are bored in

position and stamped 1, 2, 3,

and 4. Install caps with identifi-

cation stamp on right side of

engine.

Install four main bearing caps (10) along with lower bearing shells (11) and two lower thrust

washers (12). Lubricate bearings and thrust washers with engine oil prior to installation.

Apply a small quantity of International Compound No. 2 or equivalent to main bearing bolt

threads (3 or 6) and bolt head contact area.

3-227

Back to Top