TM-9-2815-205-34 - Page 358 of 596

TM 9-2815-205-34

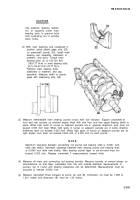

3-53. CRANKSHAFT MAINTENANCE (Cont)

(8) For all except model 5063-5398:

(a)

(b)

(c)

(d)

(e)

Install four stabilizer pIates (5), eight

hardened washers (4), eight large

bolts (3), eight hardened washers (2),

and eight small self-locking screws (1)

in cylinder block. Tighten bolts until

snug.

Strike main bearing caps (10) sharply

with a soft head hammer to seat caps.

Torque all main bearing bolts (3)

(except rear main bearing bolts) to

120-130 Ib-ft (163-177 N-m) in

sequence shown. Torque rear main

bearing bolts to 40-50 Ib-ft (54-68

N

.

m).

Strike both ends of crankshaft two or

three sharp blows with a soft head

hammer to ensure proper positioning

of rear main bearing cap in block

saddle. Torque all main bearing bolts

(3) to 120-130 Ib-ft (163-177 N-m)

again.

Torque eight stabilizer plate screws

(1) to 46-50 Ib-ft (62-68 N-m).

(9) For model 5063-5398:

(a)

(b)

(c)

(d)

Place eight spacers (9) and four

supports (8) on main bearing caps

(10). Install eight washers (7) and

eight bolts (6) in inboard holes of

support and through spacers and

main bearing cap. Tighten bolts until

snug.

Strike main bearing caps (10) sharply

with a soft head hammer to seat them

properly.

Torque eight main bearing bolts (6) to

53-57 Ib-ft (72-77 N-m) in sequence

shown.

Measure gap (D) between support (8)

and bottom of cylinder block at both

ends of support. Gap must be 0.006

to 0.023 inch. If gap is not within

limits, remove and turn support over

or switch spacers (9) and measure

gap again.

3-228

Back to Top