TM-9-2815-205-34 - Page 353 of 596

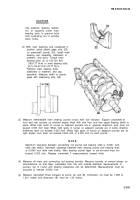

d. Inspection

(1) Inspect gear teeth for evidence of scoring, pitting, and wear. If severely damaged or worn,

replace gear.

(2) Inspect crankshaft keyways for evidence of cracks or wear. Replace crankshaft if required.

CAUTION

•

Replace crankshaft when signs of excessive overheating appear since heat treatment

has probably been destroyed.

•

Remove ridges on crankshaft journals. If ridges are not removed, localized high unit

pressures are placed on new bearing shells and short bearing life can result.

(3) Inspect crankshaft journals for ridges and grooves. Remove ridges exceeding 0.0002 inch.

NOT E

Replace crankshaft if journal ridges are greater than 0.001 inch in depth.

(4) Remove crankshaft journal ridges by working crocus cloth, wet with fuel oil, around

circumference of journals. If ridges are greater than 0.0005 inch, first use 120 grit Emery cloth

to clean up ridges, 240 grit Emery cloth for finishing and wet crocus cloth for polishing.

(5) Inspect rear crankshaft at oil seal contact surface for evidence of rough or grooved condition.

Clean up slight ridges on crankshaft oil seal contact surface with crocus cloth. If crankshaft

cannot be cleaned up satisfactorily, reposition oil seal in flywheel housing.

(6) Check crankshaft thrust surfaces for excessive wear or grooving. If only slightly worn, dress

surfaces with an X-fine sharpening stone.

NOT E

•

To detect minute cracks, use magnetic particle inspection method (reference

MlL-C-1949).

•

Crankshaft failures are rare and when one cracks or breaks completely, make a

thorough inspection for contributory factors.

(7) Inspect crankshaft for fatigue cracks which start at an oil hole and follow journal surface at an

angle of 45 degrees to axis. Reject crankshaft with cracks.

(8) Inspect main bearing shells for bright spots on backs indicating movement in bearing caps or

supports. Discard shells if this condition is present.

3-223

TM 9-2815-205-34

Back to Top