TM-9-2815-205-34 - Page 348 of 596

TM 9-2815-205-34

3-52. CYLINDER LINER MAINTENANCE (Cont)

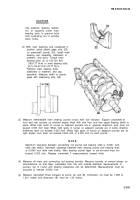

f. Fitting Cylinder Liner In Block Bore

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Wipe inside and outside of liner clean,

Clean block bore and counterbore

thoroughly.

Slide cylinder liner (1) into cylinder block

bore until liner flange rests on bottom of

counterbore in block. Do not drop or slam

liner flange against bottom of counterbore

in block.

Tap liner lightly with soft head hammer to

ensure liner flange seats on bottom of

counterbore.

Install hold-down clamp (7).

NOTE

Maximum liner height differ-

ence of 0.002 inch between any

two adjacent liners is allowed as

measured lengthwise along

center line between adjacent

cylinders.

Measure distance from top of liner flange to top of block with depth gage (8). Liner flange must

be 0.0465 to 0.050 inch below top of block.

If above liner depth limits are not met, use a new liner or install liner in another bore.

Matchmark liner and cylinder block on outboard side so liner is reinstalled in same position and

same cylinder bore as measured.

Remove hold-down clamp (7) and cylinder liner (1).

g. Installation

NOTE

Cylinder liner is installed as a complete assembly including piston, connecting rod, and

cylinder liner. See Para 3-50 or 3-51 for installation instructions.

END OF TASK

FOLLOW-ON MAINTENANCE

Para Description

3-51 Install

3-43 Install

3-50 Install’

3-34 Install

3-35 Install

3-33 Install

piston and rod assembly (models 5063-5299, 5063-5395, and 5063-5398),

piston and rod assembly (models 5063-5392, 5063-5393, 5063-539F, and 5063-539L).

cylinder head.

oil pump inlet tubes (model 5063-5299),

oil pump inlet tubes (all except model 5063-5299).

oil pan.

3-218

Change 1

Back to Top