TM-9-2815-205-34 - Page 346 of 596

3-52. CYLINDER LINER MAINTENANCE (Cont)

d. Measurements

(1)

(2)

(3)

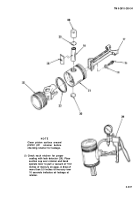

Measure outside diameter of liner at (A

and B). Diameter (A) must be 4.485 to

4.486 inches, diameter (B) must be 4.355

to 4.356 inches.

Install liner in proper bore of cylinder

block. Using cylinder bore age (4),

measure cylinder liner inside diameter at

fourteen places (C thru I) on (XZ) and

(WY) axes as shown.

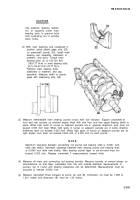

Check liner inside diameter for taper and

out-of-round. Taper must not exceed

0.002 inch on used liner and 0.001 inch

on new liner. Out-of-round must not

exceed 0.003 inch on used liner and

0.002 inch on new liner.

•

Liners, standard and oversized, have an inside diameter of 3.8752 to 3.8767 inches.

Liners are available in 0.010 and 0.020 inch oversized on outside diameter.

•

Special liner to block preformed packings are required when using 0.020 inch oversize

liner.

•

When an oversize liner is installed, stamp amount of oversize on top of cylinder block

bore adjacent to liner counterbore using metal stamping die set.

(4) Remove liner from cylinder block.

3-216

TM 9-2815-205-34

Back to Top