TM-9-2815-205-34 - Page 336 of 596

TM 9-2815-205-34

3-51. PISTON AND CONNECTING ROD MAINTENANCE - CROSS-HEAD (MODELS 5063-5392,

5063-5393, 5063-539F, AND 5063-539L) (Cont)

(3)

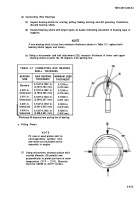

Using thickness gage set, measure side clearance of ring in piston dome (22). Refer to Table

3-8 or ring side clearance specifications.

g. Assembly

(1) Piston and Rod Assembly

(a)

(b)

(c)

(d)

(e)

(f)

(9)

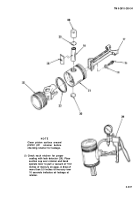

Install pin bushing (24) in piston dome (22). Bushing must slide into piston dome without

force.

NOTE

Soak ring seal in engine oil for 15 minutes prior to installation on dome.

Lubricate ring seal (23) with engine oil and install in groove on piston dome (22).

Align piston pin holes in skirt (21) and dome (22), then push skirt into position on dome.

Apply clean engine oil to piston pin (18) and piston pin bushing (24) and install piston pin.

Install spacers (19) on piston pin bolts (16). Apply small amount of International Compound

No. 2, or equivalent, to bolt threads and bolt head contact surfaces.

Install connecting rod (17), two spacers (19), and two bolts (16) on piston pin (18). Tighten

bolts finger tight.

Clamp connecting rod (17) in soft-jawed vise and torque piston pin bolts (16) to 30-35 lb-ft

(41-47 N·m). Do not exceed this torque.

CAUTION

Ensure piston pin retainers do not buckle during installation and seat completely in

counterbore with spacing even around retainer to seal properly.

(h) Insert first piston in retainer (20) in position. Place crowned end of piston pin installer (28)

against retainer.

Strike tool just hard enough to deflect retainer and to seat it evenly in skirt

(21). Install second retainer in same manner.

3-206

Change 1

Back to Top