TM-9-2815-205-34 - Page 344 of 596

TM 9-2815-205-34

3-52. CYLINDER LINER MAINTENANCE

This task covers: a. Removal

b. Cleaning

c. Inspection

d. Measurements

e. Honing

f. Fitting Cylinder Liner in Block Bore

g. Installation

INITIAL SETUP

MODELS

All

TOOLS AND SPECIAL TOOLS

Tool kit, general mechanics (App B, Item 107 )

Gage, depth (App B, Item 36 )

Remover, cylinder liner (App B, Item 86 )

Hone, cylinder (App B, Item 52 )

Gage, cylinder bore (App B, Item 35 )

Die set, metal stamping, hand (App B, Item 20 )

Micrometer set (App B, Item 73 )

Micrometer 4-5 inch

Clamp, hold-down (App B, Item 14 )

MATERIALS/PARTS

2

Packings, preformed (App F, Item 116)

EXPENDABLE/DURABLE SUPPLIES

Cleaning solvent (App C, Item 9)

Stone, sharpening (App C, Item 50)

EQUIPMENT CONDITION

Para Description

3-33 Oil pan removed

3-34 Oil pump inlet tubes removed (model

5063-5299)

3-35 Oil pump inlet tubes removed (all except

model 5063-5299)

3-43 Cylinder head removed

3-50 Piston and rod assembly removed (models

5063-5299, 5063-5395, and 5063-5398).

3-51 Piston and rod assembly removed (models

5063-5392, 5063-5393, 5063-539F, and

5063-539L).

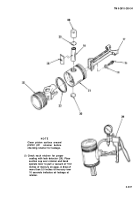

a. Removal

CAUTION

(1)

(2)

(3)

Do not insert bar in liner ports and rotate crankshaft to push out liner. Bar can damage

piston and collapse upper ring groove of cylinder block,

Loosen cylinder liner (1) using cylinder liner remover (2).

Remove cylinder liner remover (2) from

cylinder liner (1). Then remove liner from

cylinder block.

Remove two preformed packings (3) from

ring grooves in cylinder block. Discard

preformed packings.

3-214

Change 1

Back to Top