TM-9-2815-205-34 - Page 371 of 596

(4)

(5)

(6)

(7)

(8)

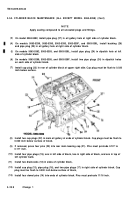

Install three compression gaskets (48),

on top surface of each cylinder bank.

TM 9-2815-205-34

four large seal rings (49), and four small seal rings (50)

Install fabricated blocking plate (51), eight flat washers (52), and eight bolts (53) on top of each

cylinder bank. Tighten bolts securely.

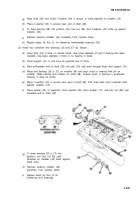

Install gasket (13), water hole cover (11), two lockwashers (10), and two bolts (9) on each side

of cylinder block. Plug hole in one of the covers with 1/8 inch NPTF pipe plug (54).

Connect air line with regulator to hole in other water hole cover (11).

Immerse cylinder block in water heated to 180-200°F (82-93°C) for twenty minutes.

(9)

(10)

Wear safety glasses when working with pressurized air system. Make certain air

pressure is fully vented before disassembly. Sudden release of air pressure can

throw debris resulting in serious personal injury. Injury to eyes and inner ears

can result from failure to properly vent block before disassembly.

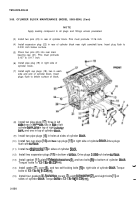

Apply 40 PSI (276 kPa) air pressure to water jacket and observe water in tank for bubbles which

indicates a crack or leak in block. Replace block if cracked.

After completing pressure test, release air pressure and

plates, seals, liners, and gaskets from cylinder block.

remove block from water tank. Remove

(11)

(12)

Compressed air used for cleaning purposes will not exceed 30 PSI. Use only with

effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.)

Blow out all passages in block with compressed air.

Dry cylinder liners with compressed air and coat with lubricating oil to prevent rust from forming.

END OF TASK

FOLLOW-ON MAINTENANCE

Para Description

3-53 Install crankshaft

3-50 Install cylinder kits (models 5063-5299 and 5063-5395)

3-51 Install cylinder kits (models 5063-5392, 5063-5393, 5063-539F, and 5063-539L)

Change 1

3-241

Back to Top