TM-9-2815-205-34 - Page 377 of 596

(6)

TM 9-2815-205-34

NOT E

•

Install main bearing bolts, bearing caps, stabilizers, and hardened washers (reference

Para 3-53).

•

Main bearing caps are numbered to correspond with their respective positions in

cylinder block. No. 1 bearing cap is located at front of block and stamped on bottom

front oil pan rail.

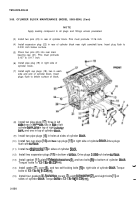

Using bore gage, measure diameters of main bearing bore (32) with bearing caps in original

position. Main bearing bore diameter is 3.751 to 3.752 inches. If bores do not meet these limits,

replace cylinder block.

(7) Measure diameter of camshaft bearing bores. End bearing bores must be 2.3750 to 2.3760

inches. Intermediate bearing bores must be 2.3650 to 2.3660 inches.

(8) Check remaining cylinder block surfaces and threaded holes for damage. Check all mating

surfaces or mounting pads for flatness, nicks, and burrs. Clean up damaged threads in tapped

holes with a tap or install helical thread inserts if necessary.

(9) Check for cracking in area between center water transfer holes and cylinder head to block bolt

holes (cam and exhaust sides). If cracks are found, replace cylinder block.

CAUTION

If cylinder block is not to be used immediately, spray machined surfaces with engine oil.

If cylinder block is to be stored for an extended period of time, spray or dip block with

corrosion preventative.

3-247

Back to Top