TM-9-2815-210-34-2-2 - Page 661 of 968

TM 9-2815-210-34-2-2

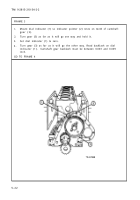

FRAME 2

1.

2.

3.

4.

5.

Coat surface of crankshaft damper and pulley assembly (1) which touches

front oil seal with lubricating oil.

NOTE

To avoid overheating and damage to damper pulley

(1), use Tempilstick on rim of damper pulley.

Heat damper pulley (1) at 200°F for 30 minutes.

NOTE

To make sure crankshaft damper and pulley assembly

is properly seated, put on heated damper and pulley

assembly, and put in and tighten retaining screw as

soon as possible before temperature of pulley and

crankshaft equalize.

Aline keyway (2) of damper pulley (1) with damper pulley locator (3).

Slide damper pulley (1) on crankshaft (4).

Take out damper pulley mounting bolt (5) and damper pulley locator (3).

IF END OF CRANKSHAFT (6) IS FLUSH WITH END OF DAMPER PULLEY BORE (7),

GO TO FRAME 7.

IF END OF CRANKSHAFT (6) IS NOT FLUSH WITH END OF DAMPER PULLEY BORE

(7) , GO TO FRAME 3

5-32

Back to Top