TM-9-2815-210-34-2-2 - Page 708 of 968

TM 9-2815-210-34-2-2

FRAME 4

Soldier A

Soldier B

Soldier A

Soldier B

Soldier A

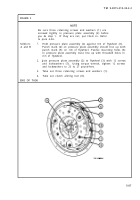

NOTE

When checking flywheel rim (4) runout, push flywheel

forward as far as it will go. Hold forward pressure on

flywheel while turning crankshaft pulley (5).

1.

Mount dial indicator (1) on flywheel housing (2) so indicator

pointer (3) rests on flywheel rim (4) as shown. Set dial indi-

cator to zero.

2.

Using engine barring tool, turn crankshaft pulley (5) slowly

to the right until soldier A tells you to stop.

3.

Read dial indicator (1) as soldier B turns crankshaft pulley (5).

When dial indicator is at the highest reading, tell soldier B to

stop.

Set dial indicator to zero.

4.

When soldier A is ready, turn crankshaft pulley (5) slowly one

full turn to the right.

NOTE

Dial indicator (1) will now read total flywheel runout. Fly-

wheel runout must not be more than 0.008 inch.

5.

Read dial indicator (1) as soldier B turns crankshaft pulley (5).

GO TO FRAME 5

5-79

Back to Top