TM-9-2815-210-34-2-2 - Page 709 of 968

TM 9-2815-210-34-2-2

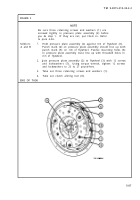

FRAME 5

NOTE

When checking flywheel face (4) runout, push flywheel

forward as far as it will go. Hold forward pressure on

flywheel while turning crankshaft pulley (5).

Soldier A

Soldier B

Soldier A

Soldier B

Soldier A

1.

2.

3.

4.

Mount dial indicator (1) on flywheel housing (2) so indicator

pointer (3) rests on flywheel face (4) as shown. Set dial in-

dicator to zero.

Using engine barring tool, turn crankshaft pulley (5) slowly

to the right until soldier A tells you to stop.

Read dial indicator (1) as soldier B turns crankshaft pulley (5).

When dial indicator is at the highest reading, tell soldier B to

stop.

Set dial indicator to zero.

When soldier A is ready, turn crankshaft pulley (5) slowly one

full turn to the right.

NOTE

Dial indicator (1) will now read total flywheel runout. Fly-

wheel runout must not be more than 0.008 inch.

5.

Read dial indicator (1) as soldier B turns crankshaft pulley (5).

END OF TASK

5-80

Back to Top