TM-9-2815-225-34-P - Page 237 of 736

TM 9-2815-225-34&P

0023 00

0023 00-7

OIL PUMP (Contd)

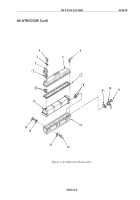

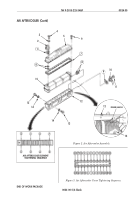

Figure 3. Oil Pump Disassembly—Big Cam III.

BIG CAM III (Contd)

Cleaning and Inspection (Contd)

6.

Inspect coupling (16) for cracks or stripped teeth.

7.

Inspect oil pump driveshaft (10) and idler shaft (21) for galling, breaks, cracks, or bends.

8.

Using micrometer or equivalent, measure oil pump driveshaft (10) and idler shaft (21) outside

diameter. Minimum outside diameter is 0.874 in (22.20 mm).

9.

Inspect woodruff key (9) for damage and woodruff key slot on oil pump driveshaft (10). Replace

woodruff key (9) and oil pump driveshaft (10) if woodruff key (9) fits loose in slot.

10.

Inspect pressure regulator plunger (22) for movement in bore of oil pump body (3). Replace

pressure regulator plunger (22) if it sticks, binds, or is excessively loose.

11.

Inspect bypass valve disc (6) for movement in bore of oil pump body (3). Replace bypass valve

disc (6) if it sticks, binds, or is excessively loose.

13

12

19

19

23

4

16

17

15

14

11

10

8

9

7

6

5

21

3

1

22

20

25

26

27

18

2

24

Back to Top