TM-9-2815-225-34-P - Page 234 of 736

TM 9-2815-225-34&P

0023 00

0023 00-4

OIL PUMP (Contd)

BIG CAM I (Contd)

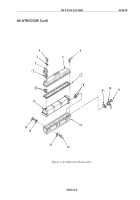

Assembly

NOTE

Lubricate all parts with OE/HDO 10 lubricating oil before

assembly.

New bushings must be line reamed to size before oil pump

assembly.

1.

Using press and mandrel, install new bushing (22) in idler gear (23). Do not press bushing (22)

more than 0.020 in. (0.508 mm) below top surface of idler gear (23). Using drill press and reamer,

line-ream inside diameter of bushing (22) to 0.8767–0.8777 in. (22.268–22.293 mm).

2.

Using press and mandrel, install two new bushings (8) in oil pump body (7). Do not press

bushings (8) more than 0.020 in. (0.508 mm) below top surfaces of oil pump body (7). Using drill

press and reamer, line-ream inside diameter of bushings (8) to 0.8767–0.8777 in.

(22.268–22.293 mm).

3.

Using press and mandrel, install new bushing (13) in oil pump housing (15). Do not press

bushing (13) more than 0.020 in. (0.508 mm) below top surfaces of oil pump housing (15). Using

drill press and reamer, line-ream inside diameter of bushing (13) to 0.8767–0.8777 in.

(22.268–22.293 mm).

4.

Using press, install oil pumping gear (12) on oil pump driveshaft (11).

5.

Using press, install oil pump driveshaft (11), with oil pumping gear (12) attached, in oil pump

body (7) until oil pump driveshaft (11) protrudes 1.035–1.055 in. (26.29–26.80 mm) above oil

pump body (7).

6.

Using press, install idler shaft (24), with large end facing up, in oil pump body (7) until large end

protrudes 0.9375–1.0 in. (23.81–25.40 mm) above oil pump body (7).

7.

Install idler gear (23) on idler shaft (24).

8.

Using feeler gauge, check clearance from oil pumping gear (12) to oil pump body (7). Clearance

should be 0.060–0.070 in. (1.52–1.78 mm). Remove and install oil pumping gear (12) until correct

clearance is obtained.

9.

Install dowel pin (10) in oil pump body (7).

10.

Install new gasket (14) and oil pump housing (15) on oil pump body (7) with two washers (21),

three new lockwashers (17), and six screws (18). Tighten screws (18) 35 lb-ft (48 N

•

m).

WARNING

Oil pump pressure regulator spring is under tension. Install

oil pump pressure regulator screw slowly and wear proper eye

protection. Failure to do so may result in injury to personnel.

11.

Install plunger (5), new pressure regulator spring (4), retaining yoke (3), new lockplate (2), and

screw (1), in oil pump body (7). Tighten screw (1) 35 lb-ft (48 N

•

m).

12.

Using pipe sealant, install pipe plug (6) in oil pump body (7). Tighten plug (6) 30 lb-ft (41 N

•

m).

13.

Install connector (16) on oil pump housing (15).

Back to Top