TM-9-2320-260-34-1 - Page 156 of 657

TM 9-2320-260-34-1

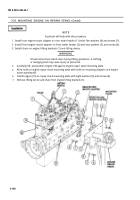

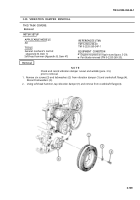

3-27. STARTING REPAIRED OR REPLACED ENGINE

THIS TASK COVERS:

a. Priming Lubrication System

c.

In-Chassis Run-In

b. Out-of-Chassis Run-In

INITIAL SETUP

APPLICABLE MODELS

REFERENCES (TM)

All

LO 9-2320-260-12

TOOLS

TM 9-2320-260-10

TM 9-2320-260-34P-1

Idle adjustment tool

(Appendix B, Item 65)

SPECIAL ENVIRONMENT CONDITIONS

Oil primary pump (Appendix B, Item 143)

Perform this procedure in a well-ventilated work

Crimping tool (Appendix B, Item 128)

area.

MATERIALS/PARTS

GENERAL SAFETY INSTRUCTIONS

Seal (Appendix D, Item 411)

Ensure engine compartment is clear of tools and

PERSONNEL REQUIRED

work material before starting engine.

Two

a. Priming Lubrication System

CAUTION

Engine lubrication system cannot be primed through bypass filter.

Insufficient lubrication will result, causing damage to engine.

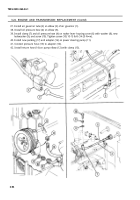

1. Remove plug (4) from gearcase cover flange (3).

2. Connect oil priming pump to orifice (1) in front gearcase cover flange (3).

3. Prime engine (2) until pressure reaches 30 psi (207 kPa).

CAUTION

Do not crank engine continuously for more than thirty seconds.

Wait two to five minutes before repeating procedure. Failure to do

so may result in damage to starter motor.

4. Close fuel shutoff valve and crank engine (TM 9-2320-260-10) for fifteen seconds while maintaining

15 psi (103 kPa) pump pressure.

5. Disconnect oil priming pump and replace pipe plug (4) in gearcase cover flange (3).

6. Check oil level (LO 9-2320-260-12).

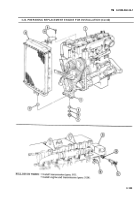

b. Out-of-Chassis Run-In

CAUTION

l If oil temperature rises sharply above 255°F ( 124°C), stop engine

immediately and correct as necessary. Failure to do so may

result in damage to equipment.

l If any leak or abnormal noise is noted, stop engine immediately

and correct as necessary. Failure to do so may result in damage

to equipment.

3-104

Back to Top