TM-9-2320-273-34 - Page 542 of 801

TM 9-2320-273-34

(3)

press rear thrust and radial bearings firmly against the pinion shoulders with a suitable

sleeve that will bear only on bearing inner race.

(4)

Install radial bearing Iockring and squeeze ring into pinion shaft groove with pliers.

(5)

Insert pinion and bearing assembly in pinion cage and position spacer or spacer

combination over pinion shaft.

(6)

Press front bearing firmly against spacer.

(7)

Rotate cage several revolutions to assure normal bearing contact.

(8)

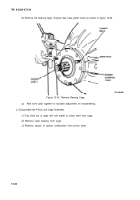

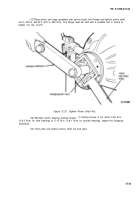

While in press under pressure, check bearing preload. Wrap soft wire around cage and

pull on horizontal line with pound scale (fig. 12-26). If a press is not available, the pinion nut may be

tightened to the correct torque, as noted in step

(9),

and preload checked.

(9)

Check for the following pressure and torque for pinion bearing preload:

(a)

Pressure to obtain correct preload: 11 tons

(b)

Nut torque to obtain correct preload: 1000-1300 Ib-ft (1356-1763 N·m).

Figure 12-26. Check Bearing Rotating Torque.

(10)

If rotating torque is not within 5-25 lb-in. (0.6-3 N·m) for new bearings or 5-15 lb-in.

(0.6-1 N·m) for reused bearings, use thinner spacer to increase or thicker spacer to decrease preload.

Example:

Assuming pinion cage diameter to be 6 inches, the radius would be

3 inches and with 5 Ibs pull would equal 15 lb-in. preload torque.

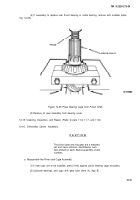

(11)

press flange or yoke against forward bearing and install washer and pinion shaft nut.

12-32

Back to Top