TM-9-2320-273-34 - Page 713 of 801

TM 9-2320-273-34

(2)

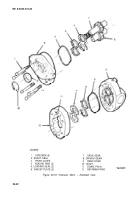

Alternately remove capscrews (23) and washers (22). Lift off the following:

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

Power plate (20)

O-ring (5)

Stationary disks (13)

Springs (11 )

Rotating disks (12)

Primary disk (10)

Pins (9)

Springs (6) and (7)

(3)

Remove snaprings (1) and (2).

(4)

Remove shaft (8) with attached bearing (3) by lightly tapping the shaft with a plastic

mallet.

(5)

Separate shaft (8) and bearing (3) by supporting the bearing inner race and applying

pressure to the shaft.

(6)

Remove piston (14) from power plate (20) by introducing low air pressure – approx-

imately 15 psi – into hydraulic inlet port, Make sure piston is pointing away from you.

NOTE

In step

(7),

do not remove backup

rings (15) and (17) unless replacement

is planned.

(7)

Remove O-rings (16) and (18) and backup rings (15) and (17) from piston (14).

b. Assembly.

(1)

Make sure that all parts are clean and dry. Use drycleaning solvent for cleaning.

(2)

Apply a light coat of hydraulic oil on new O-rings (16) and (18) and install in piston (14).

(3)

If removed, install new backup rings (15) and (17).

(4)

Assemble piston (14) into power plate (20) using a shop press, being careful not to

damage the O-rings or Teflon backup rings. Visually aline the center of the cut-outs in the piston with

the n (9) holes in the power plate (20).

(5)

press bearing (3) on shaft (8) and install into housing (4). Secure with snap rings (1) and

(2).

(6)

Install O-ring (5) in housing (4).

(7) Install springs (6) and (7).

20-30

Back to Top