TM-9-2330-342-23-P - Page 803 of 1348

DISASSEMBLY - Continued

2.

Remove cap (Figure 1, Item 1) and adapter (Figure 1, Item 2) from valve stem (Figure 1, Item 4).

WARNING

Always completely deflate tire by removing valve core from valve stem before attempting

demounting operation. After air has finished exhausting from valve stem, carefully run a piece

of wire through valve stem to ensure it is not plugged and tire is completely deflated. Failure

to comply may result in injury or death to personnel.

WARNING

High air pressure may be released from valve stem when valve core is removed. Stay clear

of valve stem after core is removed. Ensure all personnel wear suitable eye protection. Failure

to comply may result in injury or death to personnel.

WARNING

Prior to inflating or deflating tire, stand clear of trajectory area. Failure to comply may result

in injury or death to personnel.

3.

Using pneumatic tire valve repair tool, remove valve core (Figure 1, Item 3) from valve stem (Figure 1, Item 4)

and completely deflate tire (Figure 1, Item 5). Discard valve core.

4.

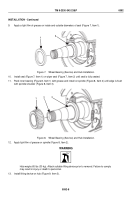

Remove wheel/tire assembly (Figure 2, Item 5) from safety guard and position on wooden block on flat surface

with nuts (Figure 2, Item 1) facing up.

1

2

4

3

5

Figure 2.

Wheel/Tire Disassembly.

NOTE

Perform Step (5) for Titan wheel assembly.

5.

Remove 12 nuts (Figure 2, Item 1) from studs (Figure 2, Item 3).

TM 9-2330-342-23&P

0093

0093-3

Back to Top