TM-9-2350-260-20-1-3 - Page 633 of 783

TM 9-2350-260-20-1-3

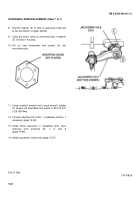

ROADWHEEL ARM REPAIR (Sheet 3 of 6)

7.

Using pry bar, remove seal (J) from retainer (G) with care.

Do not damage retainer.

Throw seal away.

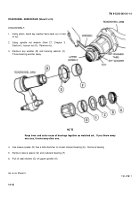

CLEANING AND INSPECTION:

1.

Using dry cleaning solvent (Item 54 Chapter 3, Section I) clean all parts, especially bearings.

2.

Check arm for cracks.

If arm is cracked or bad, turn in to support maintenance and replace with new arm.

3.

Inspect both upper and lower spindles of arm,

especially threads.

4.

Check internal splines of arm for broken, cracked, or

deformed splines.

If bad, replace arm.

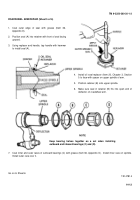

5.

Using file, smooth out any rust spots, pits, or other

damaged places on arm.

Do not file spindle.

6.

Inspect bearings (E) and (F) for missing needle

rollers and scuffs or scratches, especially on inner

races.

7.

Replace defective parts as required.

Go on to Sheet 4

TA147812

14-11

Back to Top