TM-9-2520-270-34 - Page 434 of 933

TM 9-2520-270-34

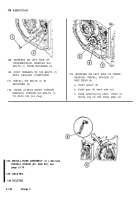

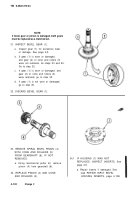

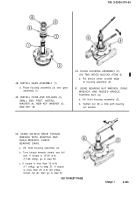

REPAIR INPUT BEVEL ASSEMBLY

This task covers: Disassemble (page 4-126). Assemble (page 4-133).

Tools:

Materials/Parts:

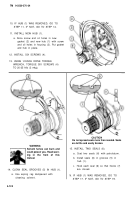

Arbor press – (Item 3, App C)

Bearing installer — (Item 9, App C)

Bearing nut wrench – (Item 15, App C)

Drag wrench — (Item 24, App C)

General mechanic’s tool kit:

automotive — (Item 33, App C)

Industrial goggles — (Item 39, App C)

Inserted hammer face holder —

(Item 39A, App C)

Inserted hammer face – (Item 39B, App C)

Inserted hammer face — (Item 39C, App C)

Leather gloves — (Item 42, App C)

Mechanical puller – (Item 48, App C)

Mechanical puller kit — (Item 49, App C)

Micrometer caliper set – (Item 52, App C)

Retaining-ring pliers — (Item 59, App C)

Snap-ring guide fixture – (Item 73, App C)

Socket wrench adapter – (Item 74, App C)

Telescoping gage set – (Item 93, App C)

Thermal drying oven – (Item 94, App C)

Torque wrench — (Item 99, App C)

Torque wrench – (Item 100, App C)

Dry ice – (Item 4, App B)

Sealant compound — (Item 11, App B)

Transmission oil – (Item 12, App B)

Wood block — (Item 1, App D)

Wood block (2) – (Item 6, App D)

Gasket

Key washer

Retaining ring

Personnel Required:

Track Veh Rep 63H10

Helper (H)

References:

TM 9-214

Equipment Conditions:

Input bevel assembly on workbench.

See page 4-94.

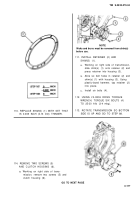

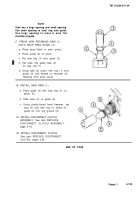

WARNING

Retaining ring is installed

under high tension. Use care

when removing retaining ring.

Personnel can be injured.

Always wear goggles.

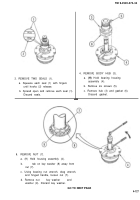

1. USING RETAINING-RING PLIERS,

REMOVE AND DISCARD RETAINING

RING (1).

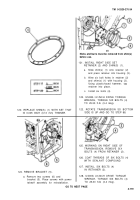

2. INSPECT SHAFT SEALS (2).

See page 2-5.

a. If

If

4-126

seals (2) are damaged, go to step 3.

not, go to step 4.

Change

2

Back to Top