TM-9-2815-205-24 - Page 121 of 856

INSTALLATION

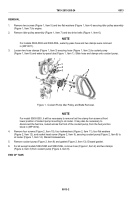

1.

If removed, install clip (Figure 1, Item 10) on tube assembly (Figure 1, Item 8). Loosely install tube assembly

in adaptor (Figure 1, Item 7).

2.

Install bracket (Figure 1, Item 2), two new lockwashers (Figure 1, Item 3), and two screws (Figure 1, Item 4)

on flywheel housing. Torque screws to 16–20 lb-ft (22–27 N·m).

3.

Install screw (Figure 1, Item 9), clip (Figure 1, Item 10), tube assembly (Figure 1, Item 8), new lockwasher

(Figure 1, Item 6), and nut (Figure 1, Item 5) on bracket (Figure 1, Item 2). Torque screw to 30–35 lb-ft

(41–47 N·m).

4.

Tighten tube assembly (Figure 1, Item 8) at adaptor (Figure 1, Item 7).

0.46 in.

(1.17 cm)

27.25 in.

(69.22 cm)

25.94 in.

(65.89 cm)

MAINT_041

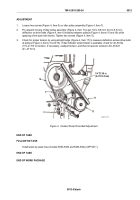

Figure 2.

Oil Level Gauge Rod Cutting Instructions.

NOTE

A replacement oil gauge rod is 61 inches (155 cm) when packaged.

5.

Cut and mark a new oil gauge rod as shown in Figure 2.

6.

Install oil gauge rod (Figure 1, Item 1) in tube assembly (Figure 1, Item 8).

END OF TASK

END OF WORK PACKAGE

TM 9-2815-205-24

0014

0014-3/blank

Back to Top