TM-9-2815-205-34 - Page 430 of 596

TM 9-2815-205-34

3-64. CYLINDER HEAD ASSEMBLY REPAIR (Cont)

NOT E

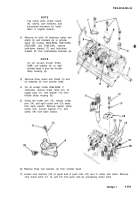

Valve seat counterbore has a diameter of 1.159-1.160 inches (29.44-29.46 mm) and a

depth of 0.294-0.306 inch (7.47-7.77 mm). Counterbores must be concentric with

valve guides within 0.003 inch (0.08 mm) total indicator reading.

(d) Immerse cylinder head in water heated to 180-200°F (82-93°C) for 30 minutes or cool

insert with liquid nitrogen.

NOT E

Install valve seat in cylinder head while head is still hot and valve seat is at room

temperature or when valve seat is chilled with liquid nitrogen and cylinder head is at

(e)

(f)

(g)

room temperature.

Place cylinder head on bench with fire

deck up. Place valve seat (68) in

counterbore with tapered face up.

Using valve seat installer (70), drive

valve seat in place until it seats solidly

in cylinder head.

Check valve seats for concentricity in

relation to valve guides using valve

seat dial gage (71).

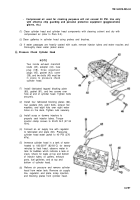

NOT E

Exhaust valve seats are

prefinished. Check for concen-

tricity after installation. Grind

valve seats only if runout

exceeds 0.002 inch (0.05 mm).

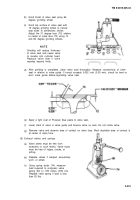

(5) Valve seat grinding

Using valve seat grinder and valve seat

grinder adapter kit, grind valve seats as

follows:

CAUTION

(a)

Do not permit grinding wheel to

contact cylinder head when

grinding valve seat. If valve

seat is ground until grinding

wheel contacts cylinder head,

then install new valve seat.

Apply 31 degree grinding wheel on valve seat.

3-300

Back to Top