TM-9-2815-205-34 - Page 433 of 596

TM 9-2815-205-34

WARNING

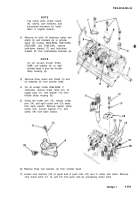

(8)

Restrain cam follower body and roller during removal from holding fixture.

Follower pin is seated on top of spring loaded plunger in holding fixture and a

sudden release could eject cam follower and cause injury to personnel.

CAUTION

Any pin hole burrs on cam follower surfaces must be removed prior to installing roller

and pin to prevent scoring of roller bushing and pin.

2. Drive pin (76) from roller (75) follower body (78) with a drift.

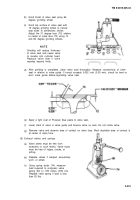

3. Place follower body (78) in groove of holding fixture with small plunger extending

through roller pin hole in one leg of follower body.

4. Coat pin (76) and roller (75) with engine oil.

5. Place roller (75) in cam follower body (78). Plunger will extend into roller bushing and

ensure accurate alignment of bushing with roller pin holes in follower body.

6. Start pin (76) squarely into follower body (78) and drive into position until pin is centered

in legs of follower.

7. Check side clearance between roller (75) and follower body (78). Clearance must be

0.011-0.023 inch (0.28-0.58 mm).

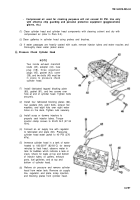

Rocker arms and shafts

Inspect rocker arm shafts and bushings for wear. Maximum shaft to bushing clearance is 0.004

inch (0.10 mm).

3-303

Back to Top