TM-9-2815-205-34 - Page 434 of 596

TM 9-2815-205-34

3-64. CYLINDER HEAD ASSEMBLY REPAIR (Cont)

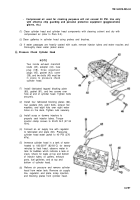

(9) Injector tube

Replace injector tubes if found leaking during pressure test as follows:

(a)

(b)

(c)

(d)

(e)

Place injector tube installer (79) in injector tube (80).

Insert pilot (81) in small hole in injector tube (80) and thread pilot in threaded hole of

installer (79).

Tap pilot (81) to drive out injector tube (80). Lift injector tube, pilot, preformed packing (82),

and installer (79) from cylinder head. Discard injector tube and preformed packing.

Thoroughly clean

material that may

Lubricate injector

cylinder head.

injector tube hole in cylinder head to remove dirt, burrs, or foreign

prevent tube from seating properly.

tube preformed packing (82) with engine oil and place in counterbore of

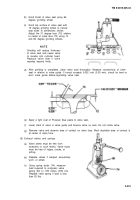

NOT E

•

There are two types of injector tube installers, a fixed tool (79) for the superseded tube

and an adjustable tool (83) for the current tube. The current tube has “606” stamped on

top flange. Either injector tube is acceptable if used with the proper installer.

•

For proper installation of current injector tube, adjustable injector tube installer must

contact bottom of injector tube before it touches flange at top. Clearance at top,

between flange and tool, must be 0.001-0.010 inch (0.03-0.25 mm).

(f) Place installer (79 or 83) in injector tube (80). Insert pilot (81) through small hole in injector

tube and thread into tapped hole at end of installer.

(g) Slip injector tube (80), installer (79 or 83), and pilot (81), into injector bore and drive into

place.

(h) Turn cylinder head fire deck up and remove installer pilot. Thread flaring die installer (84)

into tapped hole of installer (79 or 83).

(i) Apply 30 Ib-ft (41 N-m) torque to flaring die installer (84).

(j) Remove flaring die installer (84) and injector tube installer (79 or 83) from injector tube.

3-304

Back to Top