TM-9-2815-205-34 - Page 440 of 596

TM 9-2815-205-34

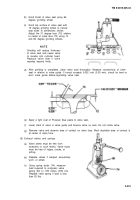

3-64. CYLINDER HEAD ASSEMBLY REPAIR (Cont)

NOT E

•

Before installing cam followers, immerse in Cindol 1705 oil heated to 100-125°F (38-

52°C) for one hour for initial lubrication of cam roller pins and bushings. Rotate cam

rollers during soaking period to purge air from bushing and roller area.

•

Install used cam followers and push rods in original locations.

(20)

(21)

(22)

Assemble lower spring seat (28), spring (26), upper spring seat (27), and push rod nut (19) on

nine push rods (20).

Install nine spring retainers (24) in bores from top of cylinder head.

Slide nine push rod (20) assemblies in cylinder head from bottom.

(23)

(24)

(25)

(26)

3-310

NOT E

Install cam followers with oil

hole away

from exhaust

valves.

Slide nine cam followers (25) in cylinder

head from bottom.

CAUTION

Cam follower must not be

cocked in bore. With cam

follower guide installed, bottom

of cam follower body must be

flush with fire deck.

Install three cam follower guides (23), six

Iockwashers (22), and six screws (21) on

cylinder head. Torque screws to 144-180

lb-in (16-20 N-m).

Measure clearance between cam follower guide (23) and cam follower legs using thickness

gages. Clearance must beat least 0.005 inch (0.13 mm).

If clearance is too small, slightly loosen screws (21) and tap corners of guide (23) with brass

drift. Torque screws again after proper adjustment.

Back to Top