TM-9-2815-205-34 - Page 435 of 596

TM 9-2815-205-34

NOT E

Reamers do not contact large inside diameter of current injector tube marked “606”.

Ream only at small inside diameter and injector nut seat.

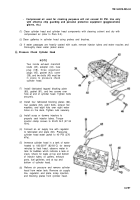

(k) Clean injector tube (80) and place cylinder head with fire deck facing down. Apply a few

drops of cutting oil on reamer flutes and carefully position finishing reamer (85) in injector

tube.

CAUTION

Turn reamers only in clockwise direction, both when inserting and removing reamers.

Movement in opposite direction will dull cutting edges on flutes.

(1) Turn finishing reamer (85) clockwise (withdraw reamer frequently to remove chips) until

lower shoulder contacts injector tube (80). Clean out all chips.

(m)

(n)

(o)

(p)

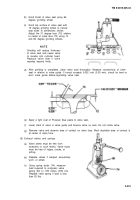

Turn cylinder head to fire deck up position. Insert pilot of tube tip refinisher (86) into small

hole of injector tube (80).

Apply a few drops of cutting oil on tube tip refinisher (86). Using a socket and revolving grip

socket wrench handle, remove excess stock so lower end of injector tube (80) is from flush

to 0.005 inch (0.13 mm) below finished surface of cylinder head.

Install injector depth gage (87) in

injector tube. Using injector protrusion

gage (88), premeasure distance from

fire deck to gage (final reading will

have to be within +/- 0.014 inch (0.36

mm) of fire deck).

Wash interior of injector tube (80) to

prepare for second reaming

operation.

3-305

Back to Top