TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 122 of 779

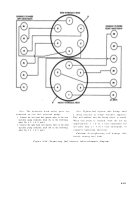

Figure 4-80

1. Using two 5 / 16-in. steel rods (A), hold fuel injection

pump

drive

coupler

sleeve

(nearest

the

pump)

stationary and rotate the other drive coupler sleeve

counterclockwise to remove backlash from the pump

drive shaft.

2. When backlash is removed and flat sides of drive

coupler mate, tighten four drive coupler bolts (B)

securely.

3. When flat sides of drive coupler sleeves (C) do not

mate when backlash is removed, the coupler sleeves

must be separated and reset. Separate coupler and push

sleeve of drive coupler on rear fan and accessory drive

housing (fig. 4-75) shaft toward drive shaft and from

hub splines. Adjust sleeve on splines so flat sides of

coupler half are alined. Torque tighten coupler bolts.

Lubricate drive coupler (fig. 4-80).

Figure 4-79. Removing fuel injection pum p

drive gear train backlash and setting

advanced unit retard position-spline d

coupler .

4-40

Note.

For proper assembly of coupler half to

diaphragm pack, place a pry bar between rea r

fan and accessory drive housing and coupler half

and apply pressure to take up the end thrust o f

drive gear. Measure clearance between couple r

half and diaphragm pack. This clearance canno t

exceed 0.050-inch or it will put undue stress on

the diaphragm pack causing early failure. If the

0.050-inch dimension cannot be achieved, it wil l

be necessary to remove fuel injection pump and

replac e

coupler hall or complete couplin g

assembly. Torque coupler half retaining nut t o

900 inch-pounds whe n

installing new couple r

half .

Figure 4-81. Checking diaphragm couple r

assembly clearance .

Back to Top