TM-9-2815-205-24 - Page 590 of 856

ASSEMBLY

NOTE

If rotor shafts have grooves from seal, install an oversize sleeve on the shaft. If an oversize

seal is installed, also install an oversize sleeve.

1.

Install oversize sleeve on blower rotor shaft as follows:

a.

Position left rotor (Figure 6, Item 8) on wood blocks and install oversize sleeve (Figure 6, Item 33) over

blower rotor shaft (Figure 6, Item 46). Using blower sleeve installer (Figure 6, Item 42), press sleeve

until shoulder of installer contacts shaft. Repeat for opposite end rotor shaft.

b.

Repeat Step 1.a. for right blower rotor.

CAUTION

New standard size seals are Teflon coated and must be installed dry to ensure proper

sealing. Oversized seals are not Teflon coated and must be lubricated prior to installing to

ensure proper sealing.

NOTE

Identify rear end plate (Figure 6, Item 30) by governor lubrication oil hole (Figure 6, Item A)

drilled in outer face of plate. Install blower seals (Figure 6, Item 29) with lips dry.

2.

Install two new standard or oversize seals in each end plate as follows:

a.

Place front end plate (Figure 6, Item 7), seal counterbores up, on press.

b.

Lubricate outer diameter of seal (Figure 6, Item 29) with engine oil.

c.

Place seal (Figure 6, Item 29), lip facing down with part number on seal facing out, in counterbore.

Using blower seal installer (Figure 6, Item 45), press seal until shoulder of installer contacts end plate.

d.

Repeat Steps 2.b. – 2.c. for second seal (Figure 6, Item 29).

e.

Repeat Steps 2.a. – 2.d. for rear end plate (Figure 6, Item 30).

CAUTION

Sealant is required when assembling blower end plates to blower housing. Failure to apply

sealant may result in air leakage between blower housing and end plates, which may affect

engine performance.

NOTE

Blower end plate and blower housing mating surfaces must be thoroughly clean and free of

any grease, oil film, or cleaner residue. Clean the surfaces with cleaning solvent.

3.

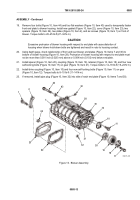

Apply a thin, even coating of Teflon-based sealing compound from sealant kit over the entire end surfaces

of both ends of the blower housing. Wipe off any excess sealant from housing bore. Allow sealant to dry to

touch before assembling housing to end plates.

4.

Place front end plate (Figure 6, Item 7), inner face up, on two wooden blocks. Install right rotor

(Figure 6, Item 9) and left rotor (Figure 6, Item 8), splined shaft ends up, in end plate.

NOTE

Install blower housing in same orientation as match marked during removal for better rotor

to housing clearances.

5.

Install blower housing (Figure 6, Item 28) over rotors (Figure 6, Items 8 and 9).

TM 9-2815-205-24

0085

0085-8

Back to Top