TM-9-2815-205-34 - Page 280 of 596

TM 9-2815-205-34

c. Cleaning/Inspection

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Compressed air used for cleaning purposes will not exceed 30 PSI. Use only with

effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.)

Wash all parts in fuel oil and dry with compressed air.

Inspect lobes and faces of oil pump rotors for scratches or burrs, and surfaces of pump housing

and cover for scoring. Remove scratches or score marks with sharpening stone.

Inspect splines of inner oil pump rotor for excessive wear.

Inspect regulator valve and by-pass valve for wear or damage. Valve must move freely in bore.

If valve is scored, clean up with crocus cloth.

Inspect valve springs for pitting and fractured coils.

Inspect lower front cover for cracks at oil seal bore and valve bores.

Inspect plug threads. Threads are acceptable, provided there is no damage that would allow

leakage and no blockage of internal passages with plug installed in hole.

d. Measurements

NOT E

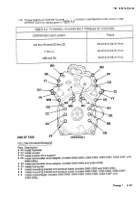

Models 5063-5299, 5063-5395, and 5063-5398 have a gear rotor thickness of 1 inch.

Models 5063-5392, 5063-5393, 5063-539F, and 5063-539L have a gear rotor

thickness of 1 1/4 inch.

(1)

(2)

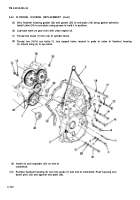

Using depth gage (34), measure clearance from face of pump housing (16) to face of inner rotor

(17) and to outer rotor (18). Clearance should be 0.001 to 0.0035 inch.

Measure clearance between inner rotor (17) and outer rotor (18) at each lobe. Clearance should

be 0.0005 to 0.011 inch.

Change 1

3-151

Back to Top