TM-9-2815-210-34-2-2 - Page 246 of 968

TM 9-2815-210-34-2-2

FRAME 17

1.

2.

3.

4.

5.

6.

Send cylinder head (1) to machine shop.

NOTE

Intake valve seat inserts (2) and exhaust valve seat

inserts (3) were taken out of cylinder head (1) before

head was sent to machine shop unless valve seat

inserts need machining.

Intake valve seat inserts (2) are bigger than exhaust

valve seat inserts (3).

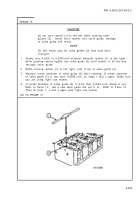

In machine shop, grind any intake valve seat inserts (2) and any exhaust

valve seat inserts (3) tagged for machining at a 45 degree angle as shown in

figure 4-5.

Mark valve seat inserts for replacement if they are worn more

than limits shown in figure 4-5.

In machine shop, if cylinder head (1) is tagged for resurfacing, take out

intake valve seat inserts (2) using engine valve seat knockout tool. Tag

intake valve seat inserts that were not marked to throw away so they can be

put back in the same place.

In machine shop, if cylinder head (1) is tagged for resurfacing, take out

exhaust valve seat inserts (3) using engine valve seat knockout tool. Tag

exhaust valve seat inserts that were not marked to throw away so they can

be put back in the same place.

In machine shop, check that intake valve seat counterbores and exhaust valve

seat inserts (2 and 3) are not damaged.

Mark damaged valve seat counterbores

for machining.

In machine shop, do frame 10 for intake valve seat counterbores under any

intake valve se-at inserts (2) just taken out.

Do frame 11 again for exhaust

valve seat counterbores under any exhaust valve seat inserts (3) just taken

out.

GO TO FRAME 18

4-227

Back to Top