TM-9-2815-210-34-2-2 - Page 239 of 968

TM 9-2815-210-34-2-2

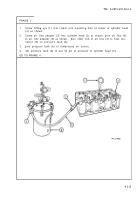

FRAME 1 0

1.

2.

3.

4.

5.

NOTE

Do this frame only if cylinder head (2) was tagged for

resurfacing or if any intake valve seat (1) was tagged

to be machined.

Do step 1 only if cylinder head (2) was tagged for

resurfacing.

If cylinder head was not tagged, do

steps 2 through 5.

Using engine valve seat knockout tool, take out all intake valve seats (1)

not tagged to be machined.

Tag each intake valve seat taken out "front

intake," "center intake," or "rear intake," so it can be put back in the

same place. Do not take out intake valve seats tagged to be machined.

NOTE

Two sizes of intake valve seat (1) are used in these

engines.

Cylinder head (2) can use a combination of

standard and 0.100-inch oversize intake valve seats.

Measure inside diameter of intake valve seat counterbore (3) for each intake

valve seat (1) taken out.

If diameter of intake valve seat counterbore (3) is 2.0580 to 2.0595 inches,

this is standard size intake valve seat counterbore. If diameter is 2.0680 to

2.0695 inches, this is 0.0100-inch oversize intake valve seat counterbore.

If diameter is more than 2.0695 inches, get a new cylinder head (2).

If inside diameter of intake valve seat counterbore is more than 2.0595 inches

but less than 2.0680 inches, tag this intake valve seat counterbore to be

machined to 0.100-inch oversize by machine shop.

Check that intake valve seat counterbore (3) is not damaged. If 0.0100-inch

oversize intake seat counterbore is damaged, get a new cylinder head (2).

If a standard size intake valve seat counterbore is damaged, tag it to be

machined to 0.100-inch oversize by machine shop.

GO TO FRAME 11

4-220

Back to Top