TM-9-2815-210-34-2-2 - Page 234 of 968

TM 9-2815-210-34-2-2

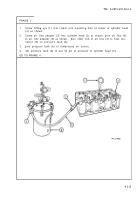

FRAME 5

1.

2.

3.

4.

Check that studs (1) are not bent, chipped or cracked and do not have

damaged threads.

Fix minor thread damage with thread chaser. If more

repair is needed, take out stud and put in new one.

Check all threaded holes in cylinder head (2).

Fix minor thread damage with

tap.

If threads cannot be fixed with tap, put in threaded insert.

WARNING

Dry cleaning solvent is flammable. Do not use near

an open flame.

Keep a fire extinguisher nearby when

solvent is used.

Use only in well-ventilated places.

Failure to do this may result in injury to personnel

and damage to equipment.

Check that gasket surface of cylinder head (2) has no burrs, scratches

or gouges.

If cylinder head gasket surface is deeply scratched or gouged,

get a new cylinder head.

Fix small burrs and scratches with a fine mill

file or crocus cloth dipped in dry cleaning solvent.

Using dial indicator, check that gasket surface of cylinder head (2) has no

scratches or gouges deeper than 0.001 inch. If any scratch or gouge is

deeper than 0.001 inch, tag cylinder head for resurfacing by machine

shop.

NOTE

Cylinder head (2) may have been resurfaced before.

If cylinder head was resurfaced before, amount of metal

machined off will be stamped on front of cylinder head

about 1/2 inch from gasket surface of cylinder head.

No more than 0.005 inch can be machined off. If 0.005

has already been machined off and cylinder head needs

resurfacing g, get a new cylinder head.

GO TO FRAME 6

4-215

Back to Top