TM-9-2815-213-34 - Page 52 of 192

word "TOP" on gasket is visible.

Be careful not to

dislodge grommets as gasket is lowered over

grommet retainers.

f.

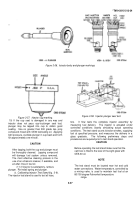

Using cylinder head lifting plate (45, fig.

B-28) as shown in figure 2-19, capscrews, lift head

with suitable hoist and lower into place over

dowels.

g.

Blow all liquid and dirt from cylinder head

capscrew holes with compressed air.

CAUTION

Keep rust preventative oil from internal

engine parts to prevent corrosive dam-

age.

h.

Coat short cylinder head capscrews with

*TM 9-2815-213-34

rust preventive lubricant and install.

Tighten each in

sequence shown in figure 3-48.

Section XIV.

Repair of Fuel Injectors

3-71.

General

This section covers the disassembly, inspection,

repair, assembly and testing of injectors (fig.

3-49).

The injector is a simple mechanical unit which

receives fuel from the fuel pump, under pressure,

and injects it through fine injector cup spray holes

into the combustion chamber.

The description "PT

Injectors" is only used to in the cate that the injector

is used with the PT fuel systems.

The PT injectors

are mounted in the cylinder head and are cylindrical

in shape.

’The V8-300 engine uses of PT type C

injector.

It consists of two major assemblies: injector

body and plunger; and the injector cup.

The orifice

descriptions below are given for functional main-

tenance purposes.

a.

Adjustable Orifice Plug.

The orifice plug

used in the inlet drilling of the cylindrical injec- tor

adjusts delivery of fuel.

Fuel delivery is ad- justed by

changing the orifice plug or by burnish- ing the plug in

operating position.

Some ori plugs have a flange and

require a gasket bene the flange.

b.

Drain Orifice.

The drilled orifice in cup E

of the injector is the drain drilling.

This orifice is fixed

in size and must not be altered in any way.

c.

Metering Orifice.

The orifice in cup end

of the injector allows fuel to enter plunger bore and

cup; do not alter in any manner.

3-72.

Disassembly

(fig.

3-49).

a.

Lift out injector plunger and spring.

Tag

mating parts.

NOTE

Injector bodies and plungers are class fits, do not

interchange.

b.

Remove and discard O-Rings

from injector

body.

c.

Disassemble clamp securing screen to injector

body.

NOTE

Do not remove adjustable orifice plug from inlet

groove.

d.

Place injector in injector cup wrench (30,

fig.

B-28) and install in injector holding fixture

(29, fig.

B-28) as shown in figure 3-50.

e.

Remove injector cup; note size markings on

injector body for future reference.

f.

Remove ball retainer, ball, and gasket from

top of injector body, discard gasket.

g.

Place injector plunger in suitable holding

device with spring retainer upward.

h.

Pull link and retainer as an assembly.

i.

Using a collet type hand tap holder, pull

injector links (fig.

3-51).

3-73.

Cleaning

Clean injector components in accordance with paragraph 2-

5.

3-74.

Inspection

Perform general inspection of components in accordance

with wear limits in repair and rebuild standards (para.

3-183).

Detailed inspection of injector components follow.

3-23

Back to Top