TM-9-2815-213-34 - Page 48 of 192

•TM 9-2815-213-34

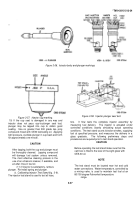

(2) Measure head height using micrometer or

vernier

calipers;

dimensions

must

not

exceed

4.4890/4.4990 inches.

(3) Restore counterbore and pocket depth at

valves and shallow counterbore area around injector port

(fig. 3-36) by grinding with a stone dressed to the

indicated contours.

b.

Regroove Cylinder Head.

If cylinder head has

been resurfaced, regroove with grooving tool (33, fig. B-

28), as shown in figure 3-37.

(1) Select scrapped injector, preferably one with

class "0" plunger bore and injector cup. Cut off cup to

expose plunger bore, to keep cup seal area intact.

(2) Install injector in cylinder head and tighten

30/35 foot-pounds torque.

(3) Select correct tool spacer block, 0.940 inch

thick. Assemble the regrooving tool, positioning largest

pilot pin so it protrudes downward

in same direction as cutter; tighten assembly in place.

(4) Rotate cylinder head and install regrooving

cutter in injector bore (fig. 347).

(5) Check position of stop in tool holder to make

certain it will not contact water hole during regrooving

operation.

(6) Adjust regrooving cutter so it protrudes

0.006/0.008 inch below stop. Rotate tool clockwise to cut

grooves. Do not rotate counterclockwise.

CAUTION

Do not attempt to cut deeper than cutter

groove depth or grooves will not form in

head.

Groove

lands

should

be

0.010/0.015 inch wide and must not

extended above head surface

Figure 3-36.

Valve and injector counterbore dimensions.

Figure 3-37.

Cylinder head regrooving.

c.

Grind

Valves.

(1) Wet grind valve from horizontal to exactly 30

degree angle.

(2) Inspect rim thickness after grinding as shown

in figure 332; if rim is less than 1/16 inch, valve is not

suitable for use and must be replaced.

(3) Check

valve

in

reamed

guide

and against

newly ground valve seat face. Pencil mark valve face and

drop into position and rotate 10 degrees. A good seat will

be indicated if all pencil marks are broken. If pencil

marks are not broken either valve seat or valve refacing

tools have not been properly adjusted; final check should

be made with vacuum tester.

3-68.

Assembly

a.

Valve Guide.

3-19

Back to Top