TM-9-2815-213-34 - Page 53 of 192

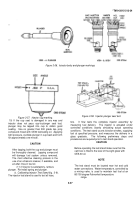

Figure 3-49.

Fuel injector PT (type C)

Figure 3-50.

Injector cup-removal/installation.

CAUTION

Never alter size of injector spray holes.

a.

Injector Cup

.

Inspect

injector cup spray

holes and tip with magnifying glass and compare

with new cup.

Discard cup if any of following

conditions exist:

(1

) Interior/or exterior abrasive wear.

(2

) Corrosion damage and effect of exces-

sive heat, usually resulting from high acid or

*TM 9-2815-213-34

sulphur content in fuel or overload operating conditions.

(3

) Enlarged or distorted spray holes, caused by

cleaning with drills, wires, or other instruments.

(4

) Plunger seat pattern covers less than 40 %

continuous area around cup, cone or plunger bore (fig.

3-

52).

Figure 3-51.

Injector Link-removal/installation.

Figure 3-52.

Plunger seat pattern.

b.

Injector Body.

(1

) Inspect injector body plunger bore for

scoring, if scores are too deep, injector body

should be replaced.

(2

) Use strong magnifying glass to check

for burs, carbon, and distorted radii in orifices.

When injector orifices are damaged, the injector

will not function properly.

c.

Injector Plunger.

(1

) Check closely for metal seizure caused

by scuffing or scoring.

(2

) Spots or surface disruption at top of

plunger or at mid-point, usually are normal re-

sults of rocker lever thrust action.

Unless metal is

displaced or wear is measureable at these points,

3-24

Back to Top